Whats Buried Underneath My Ground With 6 Wires Blue Orange White Red

Old Electrical Wiring Types

Old Electrical Wiring Types

Photo guide and History of Types of Electrical Wiring in Older buildings

- POST a QUESTION or COMMENT about old house wiring, knob & tube, old fuse panels, old house wiring condition & safety

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

History of electrical wire & electrical wiring: how to recognize knob and tube electrical wiring and unsafe "extension cord" wiring. We provide a table giving the timeline of years of use of different types of electrical wires or wire insulation and sheathing or jackets followed by a photo guide to all types of old building electrical wires.

These photos help identify types, condition, & hazards of old electrical wiring in buildings.

In this article series, we list common old building electrical wiring system safety concerns and we illustrate types of old electrical wires and devices. This article series answers basic questions about assessing and repairing the electrical service, capacity, wiring type, condition, and safety in older homes.

We also provide an ARTICLE INDEX for this topic, or you can try the page top or bottom SEARCH BOX as a quick way to find information you need.

Photo Guide to Old Electrical Wire Types

... With the increase of electric lighting (which today is used only to a very limited extent as compared with its inevitable future use) and the multiplication of wires, these dangers which exist now in a thousand different parts of the city will be manifolded many times." "So much has been said and written upon the subject of high-tension electric currents and their probable or possible danger to human life, and so many different opinions have been advanced by men whose positions serve to surround their utterances with an atmosphere of knowledge of the matter under discussion, that the mind of an unscientific public has been unable to come to any definite conclusion upon the basis of "expert" testimony.

"So much has been said and written upon the subject of high-tension electric currents and their probable or possible danger to human life, and so many different opinions have been advanced by men whose positions serve to surround their utterances with an atmosphere of knowledge of the matter under discussion, that the mind of an unscientific public has been unable to come to any definite conclusion upon the basis of "expert" testimony.

These rusty looking "pipes" may be the last remnants of the oldest and original electrical wiring used for underground electrical power distribution in the U.S. We describe these electrical power cables and provide images of and links to early electrical wiring and wire insulation methods in this article.

[Click to enlarge any image]

In the electrical wire history & old wire identification article below, we illustrate a variety of types of electrical wiring found in older buildings based on the wire insulation material (asbestos, cloth, plastic, metal) and the wire material itself: copper, aluminum, copper-clad aluminum, tinned copper.

While varying somewhat by area of the country in the U.S., Latin America, Europe, and other areas, there are recognizable generations of electrical wiring.

Proper identification of the type of electrical wire and wire insulation is useful for those seeking to guess at the age of a building or of its electrical system, and in some instances it is helpful in assessing the condition and safety of the building wiring system, such as taking note of the presence of branch circuit solid conductor aluminum electrical wire that has not been properly repaired - a fire hazard.

Below in our table we list the types of old electrical wiring included in this article series.

A 1980 US CPSC study found that aging electrical systems are a factor in the occurrence of electrical fires in homes, an observation confirmed separately by Aronstein in explaining aluminum wiring hazards in what Aronstein calls the "bathtub curve" that maps failure rates over time.

Failures occur early in the wiring system life due to original installation defects and then failures occur again at an increased rate late in the installation's life as the wiring ages and as it has been exposed to the vagaries of use over decades. This bathtub curve of failure rates is illustrated

at ALUMINUM WIRING SAFETY ASSESSMENT.

Older homes often have electrical receptacles and fixtures that are ungrounded, and many local codes do not require that they be rewired so they're grounded. Still, grounding is worth adding to your system because it adds protection against electrical shock.

But Dini points out that "... most of the hazardous conditions found in the 30 houses [studied] could be attributed to a lack of compliance with a specific code requirement". (Dini 2008).

Above: two types of branch circuit electrical wire insulation are shown in our photo: braided fabric wire insulation, probably cotton covered with wax or varnish, and newer plastic wire insulation.

The braided fabric wire insulation was found on a 1960's fluorescent light ballast, while the plastic wire was used in the branch circuit wiring for the light where that ballast was employed. The old style ballast and its wire could have dated from the 1950's.

Electrical Wiring History Timeline

The table below gives approximate dates of origin and use of various types of electrical wire used in buildings. Also see the detailed article we provide for each electrical wire type, as more complete history will be provided in those articles.

Electrical Wire Type & Use Timeline | ||

| Wire Type | Dates | Comments & More Information |

| Telegraph Wires | 1844 | First commercial telegraph wires, Iron conductors, replaced by copper by 1913, low-voltage only. |

| Telephone Wires | 1876 | Early copper conductors, insulated, low-voltage only |

| Edison Solid Iron Tubing | 1885 - 1910 | Also: existing gas pipes converted to electrical use Details at SOLID PIPE EDISON DC CABLE HISTORY |

| Gutta Percha insulation | 1885 | Insulation on smaller conductors |

| Knob & Tube | 1880 - present | KNOB & TUBE WIRE IDENTIFICATION Widespread use declined after 1940, Details at KNOB & TUBE WIRING |

| Paper wire insulation | 1890 - 1910 | Oil-impregnated paper Paper still used between PVC-insulated conductors |

| Armored cable aka "BX" wire aka "Greenfield" | 1898 - present | ARMORED CABLE or BX WIRE IDENTIFICATION |

| Copper conductors | 1913 - present | Possibly earlier. |

| Asbestos insulated wire | 1920 - 1988 | ASBESTOS WIRE INSULATION IDENTIFICATION Details at ASBESTOS ELECTRICAL WIRE INSULATION. |

| Rubber insulated wire | 1922 - 1950 | RUBBER WIRE INSULATION IDENTIFICATION Vulcanized rubber (VIR / VRI) insulation on copper conductors, Rubber exterior sheathing ca 1960, |

| Tinned copper wire | ca 1925 - | TINNED COPPER WIRE IDENTIFICATION Details at TINNED COPPER ELECTRICAL WIRE |

| Lead wire sheathing | 1930 - 1960 | Flexible lead cable sheath covering rubber or pvc-insulated conductors |

| Cloth or fabric wire inslulation ( NMC) | 1933 - present | CLOTH WIRE INSULATION IDENTIFICATION Includes varnished & other fabric sheathed cables, Details at FABRIC NMC WIRE INSULATION IDENTIFICATION |

| Electrical conduit, metal | 1940 - present | CONDUIT WIRE IDENTIFICATION Details at ELECTRICAL CONDUIT, METALLIC |

| XLPE | 1950 | Replaced paper insulation (medium voltage) |

| Copper electrical conductors with aluminum ground | 1948-1960 (est) | UNIDENTIFIED Fabric Insulated Copper Conductors with Aluminum Ground |

| Aluminum electrical wire | 1965 - 1973 | ALUMINUM ELECTRICAL WIRE Details at ALUMINUM WIRING IDENTIFICATION |

| Copper-clad aluminum wire | 1972 - 1975 | COPPER CLAD ALUMINUM WIRE IDENTIFICATION Details at COPPER-CLAD ALUMINUM WIRE |

| Plastic insulated wire (NMC) | 1950 - present | PLASTIC NMC WIRE INSULATION IDENTIFICATION Earliest uses in Germany ca 1930 PVC sheath & wire insulation introduced 1952, i Includes Underground Feeder (UF) cables |

| Electrical conduit, plastic, flexible | 1990 - present | Details at ELECTRICAL CONDUIT, NON-METALLIC |

| Lamp cord | EXTENSION, LAMP, ZIP CORD WIRE IDENTIFICATION | |

| Theater wire (asbestos?) | THEATER WIRE IDENTIFICATION | |

| Wire loom conduit | WIRE LOOM or WIREDUCT WIRE CONDUIT | |

| Wood wire moldings | 1900 - 1928 | Banned in North America in 1928 |

Notes to the table above

- Distinguish between insulation on the electrical conductors themselves, and the exterior sheath that covers two or more electrical conductors. Those are often different materials. For example a fabric exterior sheathing may cover rubber-insulated copper or tinned-copper conductors in older electrical wiring.

- Eland Cables, "What is the history of electrical cables?" - UK & Ireland, 020 7241 8787 sales@elandcables.com retrieved 2022/03/17 original source: https://www.elandcables.com/the-cable-lab/faqs/faq-what-is-the-history-of-electrical-cables

- See also ELECTRIC WIRE HISTORY RESEARCY & PATENTS below on this page

Aluminum Electrical Wiring Types

[Click to enlarge any image]

As you see in the photo above, typically aluminum electrical branch circuit wiring was plastic-covered.

Aluminum wiring has been studied since about 1945, and began appearing in homes in North America as early as 1965.

In that year Kaiser Aluminum and Chemical Corporation (KACC) began marketing KA-FLEX solid-conductor aluminum wiring (shown here).

Watch out: Unless it has been properly repaired or replaced, aluminum wiring in homes or other buildings is a serious fire hazard.

See complete details about aluminum electrical wiring

at ALUMINUM WIRING IDENTIFICATION

and at ALUMINUM WIRING GUIDE for HOME INSPECTORS for a discussion of safety hazards associated with aluminum wiring.

Watch out: improper "repair" of aluminum wiring using connectors that do not successfully prevent overheating (CO/ALR, CU-AL-stamped devices, and the Ideal No. 65 purple Twister), may increase the fire hazard in a home and worse, may lead occupants to ignore danger signs of a possible fire, thinking that their wiring is now repaired and safe.

Copper Electrical Wire with Aluminum Sheathing under Plastic

Pulled this stuff out of a house. Couldn't get over how difficult it must have been to install. Aluminum sheath, cloth covered copper., three wire has loom and filler.

Thanks Sean we'll add that to the collection of wiring types - it'll help other readers - and I'll do some research to see what background I can find.

It would be helpful to know the country and city of the home where this was found as well as the age of the home and whether or not there are any special environmental concerns that might have led to the use of this wiring.

Also we need to see the stripped back wire ends to show other readers that this is copper wire in an aluminum sheath

I suspect this was a form of pre-wired "conduit" using semi-flexible aluminum tubing. I've included your photo and further comments and research in the article above on this page.

Solid but flexible metal conduit (with rules about just how it may be bent) is using solid aluminum and is one of several forms of pre-wired conduit that was probably intended for use in hazardous areas.

I've on occasion seen such industrial products used in the construction of private homes, perhaps because the owner or builder had a line on some "free" materials that fell off of the truck. So to speak.

Armored Cable Electrical Wiring "BX" & "Greenfield" - Metallic Sheathed Electrical Wire

The photo above illustrates two generations of metallic-sheathed armored cable or "BX" electrical wire.

The larger diameter wider-wrapped armored cable is probably Greenfield flexible steel armored cable, a wiring type patented in 1898.

Where does "BX" come from? Dini (2006) explains that this cable was produced by Greenfield, one of its inventors, in two experimental forms AX and BX (X = experimental). The second version "B" was the more successful version that was produced.

The term "BX" stuck on later versions of flexible metal armored cable: the smaller-diameter modern "BX" wire is in the left of the photo and connects to the left side of the electrical box.

Also

see ELECTRICAL WIRE STRIPPING TIPS where we discuss stripping and working with BX or armored cable.

Greenfield's original design used multiple strands of copper conductors, typically twisted, and surrounded by a pitch-like insulating material like that we illustrate in Edison's original underground electrical cables shown

at STEAM BOILERS GENERATORS CONTROLS, PRATT.

Greenfield Cable Patented Flexible Conduit

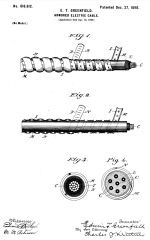

Here are the original image and a text excerpt from Edwin T. Greenfield's 1898 patent:

My invention is directed particularly to improvements in electric cables designed for ocean service, and has for its objects,

first, to devise an armored cable of such nature that the insulation of the cable will be thoroughly protected from the attacks of borers or other insects or animals which usually attack cables of this nature when sunk in the body of the ocean

second, to devise an armored cable of such a nature that its exterior armor will fully protect it (the cable) from unnatural wear when it is suspended over ledges of rock in the body of the ocean;

third, to provide a cable of the nature indicated in which the armor is of steel, phosphor-bronze, or any preferred metal having the desired strength and qualities for adapting it for use in the ocean and in making such armor of a flexible nature, so that the completed cable may be wound upon a drum in the usual way when it is desired to lay it in the bed of the ocean, and,

fourth, to provide a lead or equivalent covered cable with a flexible protecting armor which will protect the lead covering from the action of metal slivers when drawn into a conduit.

Also see a brother wiring material sold without conductors in this article:

CONDUIT WIRE IDENTIFICATION

Below: an early advertisement for Cres-Flex armored cable or "flexible metallic-sheathed" wire:

Crescent Insulated Wire & Cable Co. also made fabric-insulated electrical wire described further

at FABRIC NMC WIRE INSULATION IDENTIFICATION.

Asbestos-Insulated Electrical Wiring

The asbestos-insulated electrical wiring wire loom or "flexible conduit" shown above is discussed in detail

at ASBESTOS ELECTRICAL WIRE INSULATION.

Asbestos electrical wire insulation is reported by some websites as "common" but I suspect its use was most common in applications where extra heat resistance and fire safety were a concern, such as theater wiring, electrical appliance wiring, aircraft wiring.

More examples of non-asbestos wire loom are given later in this article.

Cloth & Varnished-Cloth Insulated Electrical Wiring

Above: varnished-cloth electrical wire on the ballast used in a fluorescent light fixture in a 1960's home built in northern Minnesota.

See complete details about cloth or fabric-covered electrical cable or wire

at FABRIC NMC WIRE INSULATION IDENTIFICATION

Asbestos-impregnated type AVB cloth wiring insulation is discussed separately

at ASBESTOS ELECTRICAL WIRE INSULATION.

Conduit for Electrical Wiring

Metal and more recently plastic tubing are both used as conduit for routing and protecting electrical wiring in a wide range of applications.

Dini (2006) notes that the earliest wire conduit material (ca 1910) was made of wood moldings grooved to carry the conductors and covered with a wooden cap.

But you won't find that material today except perhaps in an authentic or un-restored older building. Modern conduit is made of rigid metal that can be bent into elbows, plastic that includes pre-bent elbows, and flexible metal and plastic ENT materials.

Below you will notice large diameter plastic conduit bringing power to an electrical sub panel.

Electrical conduit is also sold in a flexible metal design that should not be confused with BX or Greenfield armored cable: this flexible metal conduit looks like BX or armored cable but is sold "empty".

Below this section of flexible metal conduit was a left-over scrap that had had three wires inserted through the protective cable.

To compare flexible conduit with armored cable, BX, or Greenfield wiring,

see ARMORED CABLE or BX WIRE IDENTIFICATION in this article.

In nearly all new outdoor air conditioner & heat pump installations the electrician uses a pre-wired waterproof electrical conduit whip (photo above).

For details about metal electrical conduit, please see our separate article

ELECTRICAL CONDUIT, METALLIC where we describe just about all of the types of modern electrical conduit materials including some not shown above.

Flexible Solid Aluminum Conduit Wiring

Above: metal clad cable using solid aluminum semi-flexible conduit pre-wired with fabric-insulated copper conductors, contributed by reader Sean 2019/08/11.

Sean wrote:

"Pulled this stuff out of a house. Couldn't get over how difficult it must have been to install. Aluminum sheath, cloth covered copper, three wire has loom and filler."

Excerpt from NFPA 70-2005

In Class I & II, Division 2 hazardous areas, the conduit itself cannot be used as the grounding means. A bonding jumper must be installed in accordance with NEC Section 250.102.

Flexible metal conduit is available with steel or aluminum armor in trade size 5 ⁄16" to 4".

With few exceptions where 5 ⁄16" and 3 ⁄8" trade sizes are used, Code prohibits use of conduit less than "d" trade size.

Bends in concealed work are restricted to 360 degrees total.

No angle connectors are permitted in concealed raceway installations.

Portions of this section reprinted by permission from NFPA 70-2005, National Electrical Code®, Copyright © 2004, National Fire Protection Association, Boston, MA.- retrieved 2019/08/11, original source:

METAL CLAD CABLE, ARMORED CABLE AND FLEXIBLE METAL CONDUIT [PDF] manufacturer's data sheet from Farnell Electric, http://www.farnell.com/datasheets/165782.pdf

Copper-Clad Aluminum Electrical Wiring

[Click to enlarge any image]

The photograph of copper-clad aluminum electrical wire shows the wiring sheathing markings [click to enlarge]. This NMC or non-metallic-sheathed cable electrical wire was observed in a 1974 Edina MN townhouse and was connected to an FPE electrical panel.

Unlike aluminum electrical wire used in branch circuits (a fire hazard), copper-clad aluminum wire performs about as well as copper wire and is considered safe for use in homes provided of course that the wiring has been correctly installed.

Photograph above provided by and used with permission of Roger Hankey, a Minnesota home inspector.

See details about copper-clad aluminum electrical wiring

at COPPER-CLAD ALUMINUM ELECTRICAL WIRE

Extension Cord Electrical Wiring

At NUMBER of CIRCUITS in OLD BUILDINGS,

we explain that the use of zip cord or extension cord mounted on or through walls and ceilings to add lighting circuits or receptacles is improper, unsafe (a fire hazard), and is often an indication that the building does not have enough circuits for modern usage.

Watch out: where we find zip cord electrical wiring it is important to see what other unsafe wiring practices that same installer may have followed.

Above the same do-it-yourself-er has left at least six, probably more unsafe details at this electrical receptacle:

- Missing strain relief on armored cable

- Extension cord wiring used to extend the circuit

- Second circuit (below the armored cable) stripped back without connection to the electrical box at all

- Electrical box too small for number of conductors

- Electrical box inadequately secured to the building

- No cover plate on the electrical box.

Below we show the front of this add-on electrical receptacle. One thing is "correct" though: the installer used a two-prong receptacle that excludes a third ground prong opening - as he should have done as the circuit does not include a grounding conductor.

Black, Gray, Silver & White Colored Fabric Covered NMC Electrical Wire Insulation

The exterior insulation on cloth or fabric-insulated NMC electrical wires are often black, silver, or white but may also be black or brown.

The exterior insulation on cloth or fabric-insulated NMC electrical wires are often black, silver, or white but may also be black or brown.

The individual conductors within the cable may be insulated in rubber or fabric-covered rubber or they may be insulated by plastic in later wiring products.

See details including the history of manufacturers of fabric-insulated wire along with dates, trademarks, and identifying photographs of a number of these cloth-insulated wire types.

at FABRIC NMC WIRE INSULATION IDENTIFICATION where we also discuss Paraflex & Paranite Insulated Electrical Wiring

Also see ASBESTOS ELECTRICAL WIRE INSULATION.

Knob & Tube Electrical Wiring

The earliest form of electrical wiring system in buildings in the U.S. was knob and tube: separate hot and neutral wires were hung in air, spaced 2 1/2" or more apart, and insulated from contact with wood framing by ceramic knobs or where wire had to pass through a wood framing member, ceramic tubes.

Both of these are shown in our photo below. Knob and tube wiring diminished in popularity in North America by 1940, but continued to be installed as new work in some locations (including New York) until about 1975.

This wiring as pre-existing or "old-work" electrical wiring, is still described in the U.S. National Electrical Code (2005) in Article 394.

The knob and tube wiring shown above is discussed in detail

at KNOB & TUBE WIRING - topic home, where we discuss assessing the condition of knob and tube wiring and issues concerning improper extensions of knob and tube circuits.

Plastic or Nonmetallic Cable (NMC) Insulated Electrical Wiring: Romex Cable Wiring

Dini (2006) notes that NMC or plastic-insulated wire or "Romex" has been in use in the U.S. since about 1926.

Plastic NMC began replacing both rubber wire insulation and fabric-based wire insulation in the U.S. in the 1950's. PVC here refers to plastics based on polyvinyl chloride.

Plastic or thermoplastic nonmetallic cable such as that shown below, still referred to by many electricians as "Romex" cable, has been in use since the 1960's and in the U.S. became very widely used in new residential construction by 1970, completely replacing fabric-based wire insulation products.

See FABRIC NMC WIRE INSULATION IDENTIFICATION.

But in some jurisdictions including some large cities, local electrical codes require metallic armored cable

(ARMORED CABLE or BX WIRE IDENTIFICATION) or electrical conduit rather than plastic NMC.

Also see ROMEX SPLICE CONNECTORS

Rubber-Insulated Electrical Wires

It's fair to say that rubber in a somewhat different form was the first electrical wire insulating material, at least in the U.S., dating from Edison's 1892 patent from which we excerpt this part of Edison's wire insulation description:

The object of my invention is to effectively insulate wire, so that it will be waterproof and capable of being used in moist places and even under water without detriment to its insulating qualities, and also fire-proof, so that if by accident the wire becomes red-hot the insulating-covering will not be set on fire and burned, but only oxidation will result, which will leave the wire pyro-insulated.

The main feature of the invention is the use as an insulating-covering of a mixture of rubber with an infusible material in the form of a powder.

But actually earlier electrical power cable and wiring insulation appeared as rope, tarred fabric, and even wood. However the rubber insulated wire illustrated by Edison's 1892 patent represented the first economical branch circuit conductor wire insulation approach that could be mechanically and economically produced in high volume.

More electrical generator equipment dating from Edison's day and still on display at the Pratt Institute can be seen

at STEAM BOILERS GENERATORS CONTROLS, PRATT.

Mixed-Media wire: rubber-insulation over plastic-coated copper electrical wires

Above: This wire was a short section of extension cord that had been used to connect a permanently-mounted fluorescent light fixture to power by plugging it into a wall-mounted electrical receptacle.

Below: this is a sample of plastic-insulated multi-strand electrical wire that was encased in the rubber jacket shown above.

When the light failed to operate, the author, on disassembly, found that the insulation on this wire was badly deteriorated, crumbling, and unsafe.

In our rubber and fabric wire insulation photo below you can see that inside the outer rubber wire jacket these conductors were insulated by fabric-covered rubber.

The color codes (white = neutral, black = hot) can be faded and hard to recognize on these wires unless you strip back more of the insulating jacket. The wire shown below combines the hot and neutral wires in an external rubber jacket. But the earliest electrical wiring systems in the U.S. used the knob and tube system.

See KNOB & TUBE WIRE IDENTIFICATION in this article or for details about knob and tube wiring

see KNOB & TUBE WIRING

Sometimes you may find tinned-copper electrical wire in these older conductors. Don't mistake tinned-copper for aluminum electrical wiring.

Power Cable for Electric Welder

The damaged power cable shown above was used with a 1970's electric welder.

Beneath the heavy rubber exterior of the welder power cable we see a cloth fabric that might be an asbestos fabric needed for extra heat resistance.

Other readers familiar with this welder cable are invited to use the page top or bottom CONTACT link to offer more information.

Solid Iron Tubing or Steel Pipe & Pitch Insulated Electrical Cables

Above: Above we're looking at the cut-end of what is most likely a section of original DC or continuous current distribution cabling salvaged from a NYC trench.

The solid copper core is much thicker than my thumb

The solid copper core was wrapped in rope to insulate it from the iron pipe and the space between that cable and the surrounding iron pipe was filled with a pitch-like substance. - C.M.

Details are

at SOLID PIPE EDISON DC CABLE HISTORY

Theater Electrical Wiring

In theaters where electrical wiring is often temporary, we often find surprising and possibly unsafe installations. The rubber-coated wires shown below were observed in a New York theatre and looked better than what my brother-in-law Matt, a theatre electrician, could produce.

Theater fires are particularly dangerous as there is likely to be a crowd stampede to exits, poor lighting, and lots of combustible materials.

In my home town, Richmond VA, the Hippodrome theater, opened in 1914, caught fire in 1945 when I was just two (so I'm not responsible). The fire was thought to have been electrical in origin.

The U.S. NEC addresses theater wiring in several articles such as Article 530 - buildings or portions thereof used as studios using motion picture film or electronic tape more than 7/8" in width, Article 540 - wiring for motion picture projector rooms, and others.

See ELECTRICAL SAFETY in the THEATRE [PDF]

Tinned Copper Electrical Wire

Above, we see both older fabric-covered electrical conductors and newer plastic-insulated wires in an electrical panel. The bare copper wire that is nearly black was a clue in tracking down a neutral and ground wiring failure at this building.

Above, the same rubber-insulated electrical wire discussed earlier is also used to illustrate the dull silvery colored metal wire observed where tinned copper electrical wiring is installed.

Watch out: tin-plated copper wire is a completely different product that, because its conductors sport a thin plated silver colored surface, might be mistaken for unsafe aluminum wire. It is not aluminum and it is safe unless, as with any electrical wiring, it has been damaged in some manner.

Not all rubber insulated copper wire is plated, but if you suspect that the silvery-colored wire is plated copper, it's easy enough to determine: with the wire disconnected from any power source, scratch the silver colored surface of the rubber-insulated wire and you'll see its red copper interior.

In REDUCE THE AL WIRE RISK: DETAILS, as well as in Aronstein (2011), Aronstein describes plated-copper wire as:

Plated copper wire [tinned copper wire] is relatively common in older homes, and it looks like aluminum wire. It was commonly used with rubber-based insulation. Identification can be made by careful inspection of a cut end of the wire.

In general, plated copper wire would not be present in nonmetallic sheathed cable ("Romex"), it is most generally found in metallic sheathed cable ("BX"). Cable of the "BX" type is not likely to contain aluminum wire. - Aronstein (2011)

At TINNED COPPER ELECTRICAL WIRE we provide additional discussion of how to avoid confusing tinned copper wire or tin-plated wire with aluminum wire such as the tinned copper multi-stranded wire shown below.

The heavy fabric braid wires shown in the left of this photo may be mistaken for Wireduct, also referred to as All-Weather Loom - shown below. It is not. This is a fabric- and rubber-insulated multi-strand electrical wire.

Wireduct or Wire Loom flexible conduit

Wire loom or all-weather loom was sold as a non-metallic flexible conduit for protection of electrical wiring in buildings.

Wireduct all-weather loom wire insulation was produced in sizes from 1/4" to 2 1/2" in diameter and was described as having a flame-retardant finish and low moisture absorption.

The two wire loom fabric conduit photos above were provided by InspectApedia.com reader Jared.

The asbestos "wireloom" shown earlier on this page may be an example of this product too, designed for improved flame resistance in theaters. You may find wireduct or wire loom on knob and tube electrical wiring systems as well as other older building electrical wiring.

In the unfortunate electrical wiring situation shown above, a reader mailed us this photo of white (probably-asbestos) wire loom-wrapped electrical wires and splices left exposed in the floor of her attic. We caution that with this sort of electrical work visible, one must worry about what other work was done on the building by the same installer.

Wire Loom is still sold as a cabling protection sleeve made in its current (2016) form as a colored nylon flexible slit corrugated tubing or as black polyethylene flexible tubing.

As we illustrate above in Jared's photos, asphalt-impregnated cloth wire loom is also available and is used in antique and original restoration work (photos adapted from EBay advertisements 2016/02/10). - Thanks to home inspectors Roger Hankey and Kevin O'Hornett for added details about wire loom insulation, 2016/02/09

Below: a non-split wire loom: Whittaker Fabric Wire Loom, 3/8" diameter.

This is an asphalt-impregnated cotton wire loom typically used in automotive applications. Some antique wire loom products or wiring sleeves are constructed with a combination of asphalt-impregnated cotton/poly paper blend coated with asphalt for moisture resistance.

Special thanks to Minnesota home inspector Roger Hankey for assistance with material for this article. Roger Hankey is principal of Hankey and Brown home inspectors, Eden Prairie, MN. Mr. Hankey is a past chairman of the ASHI Standards Committee. Mr. Hankey has served in other ASHI professional and leadership roles.

Contact Roger Hankey at: 952-217-1617 (MN) / 970-393-6604 (CO) - rhankey@hankeyandbrown.com. Mr. Hankey is a frequent contributor to InspectAPedia.com.

Electrical Wire History & Research

Following are examples of early U.S. patents that help provide dates for types of electrical wiring and electrical wire conductor insulation and insulating sheathing.

- Edison, Thomas A. "Electrical Indicator" U.S. Patent 307,031, issued October 21, 1884.

Abstract:The object of my invention is to produce an efficient apparatus for indicating variations of electro-motive force in an electric circuit, preferably for use in connection with systems of electrical distribution to show the changes in pressure in the various parts of the district.

Above: illustration from Warner's 1890 patent of a method for manufacturing electric conductors.

- Warner, E.P., METHOD of MANUFACTURING ELECTRICAL CONDUCTORS [PDF] US466268A [PDF] U.S. Patent US466268A issued August 5, 1890

Excerpt:

My invention relates to the manufacture of double-stranded electric conducting-cords; and its object is to produce a cord which shall be of moderate diameter, thoroughly insulated, and at the same time protected from external injury.

- Edison, Thomas A. ELECTRIC CONDUCTOR [PDF] U.S. Patent 470,924, issued March 15, 1892.

Excerpt:To all whom it may concern: Be it known that I, THOMAS A. EDISON, o Llewellyn Park, in the county of Essex and State of New Jersey, have invented a certain new and useful Improvement in Electrical Conductors, (Case No. 732,) of which the following is a specification.

The object of my invention is to effectively insulate wire, so that it will be waterproof and capable of being used in moist places and even under water without detriment to its insulating qualities, and also fire-proof, so that if by accident the wire becomes red-hot the insulating-covering will not be set on fire and burned, but only oxidation Will result, which will leave the wire pyro-insulated.

The main feature of the invention is the use as an insulating-covering of a mixture of rubber with an infusible material in the form of a powder.

I prefer to employ crude gum rubber, which I soften or partially dissolve by a suitable solvent such as benzole-and then mix in a suitable mixing or kneading mill with about twice the quantity of the infusible powder, such as kaolin, chalk, carbonate of zinc, or phosphate of lime.

The proportions of these substances will vary with the use to which the wire is to be put.

They must be such that the covering, when placed upon the wire, will be flexible, water-proof, and a good insulator, and such that when the wire is heated the covering will not burst into a flame at any temperature up to the melting-point of the wire.

While pure rubber is an almost perfect insulator, it is so inflammable when used alone or in conjunction with cotton or other fabric that it cannot be safely used in electric-light wiring.

In my invention the infusible substance mixed with the rubber serves to prevent the flame, and a very considerable quantity thereof may be used without lowering the insulating and water-proof qualities too much for ordinary use.

If the wire is to be used in situations where it requires to be bent sharply and so must be very flexible, or if it is to be used in very wet places, then the minimum amount of infusible material which will make the covering non inflammable must be used; also, the amount of rubber to the infusiblc material will vary, according to the character of the latter.

- Sawyer, W.H. ELECTRIC CABLE [PDF] U.S. Patent US473353, April 19, 1892

Excerpt:

My present invention relates to improvements in that class of electric cables which are especially designed for telephone service, but which are also equally adapted for telegraph purposes, the object being to provide an electric cable wherein the wires or conductors of each metallic circuit are kept equidistant from each other to produce an equilibrium of inductive effect and to provide the greatest amount of separation within the smallest possible space, thereby securing a low specific inductive capacity combined with high insulating properties.

- Greenfield, Edwin T. ARMORED ELECTRIC CABLE U.S. Patent 616,612, issued December 27, 1898. Filed 1986

Excerpt:Be it known that I, EDWIN T. GREENFIELD, a citizen of the United States, residing at New York, in the county of New York and State of New York, have made a new and useful Invention in Armored Electric Cables, of which the following is a specification.

- Greenfield, Edwin T. "Means for giving rigidity to elbows or turns of flexible conduits." U.S. Patent 644,858, issued March 6, 1900.

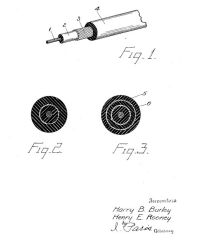

Above: electrical wire insulation illustration from Burlery's 1923 patent cited below.

- Burley, Harry B., and Henry E. Rooney. INSULATED ELECTRIC WIRE [PDF] U.S. Patent 1,458,803, issued June 12, 1923. Application US534469A filed in 1922.

Excerpts:

Our present invention relates to electric wires or cables of the class in which rubber or rubber compound' is used for insulating purposes. Our invention relates more specifically to wires or cables covered by a vulcanized rubber compound designed for use in the transmission of high voltages.The common method of insulating such wires is to increase the thickness of the rubber wall when it is desired to transmit a higher voltage.

It is found, however, that by this method a point is reached beyond which the increase in the thickness of the wall does not give any commensurate advantages in the voltage carrying capacity of the wire or cable.

It is the object of this invention to increase the dielectric strength of the insulation of the rubber covered wire or cable, to increase their voltage carrying capacity and to render such wires or cables capable of withstanding a higher voltage without increasing the thickness of the insulating wall of wire or cable.

We accomplish these objects by embedding within the rubber compound insulation one or more interlayers of cotton, flax, hemp or similar fibrous material of a flexible character.

An interlayer of such material has a conductivity substantially greater than that of rubber. This interlayer, therefore, acts to distribute over the inner surface of the rubber, surrounding said interlayer material, any leakage of the current through an interior portion of the insulation.

Antique Lamp ("Light Bulb") Identification, Catalogs, History, References

This discussion has moved

to ANTIQUE LAMPS (BULBS) & CONNECTOR TYPES

Reader Q&A - also see the FAQs series linked-to below

What kind of wiring could this be? It is long-ago decommissioned. Single conductor in a very stiff tar or rubber outer insulation with shiny crystals in it. There is also decommissioned knob and tube in some places, but this wire does not use knobs or tubes.

On 2022-04-18 by Inspectapedia Com Moderator - how do I change to a regular plug fitting?

@Christine Freer,

Sure. A "light fitting" - connected sewing machine is unfamiliar to me - please post a photo of the machine's power cord connecting-end and another (one photo per comment) of the whole sewing machine and a third of its data tag - that will help us research and answer more-fully.

But in general, if there are only two wires one will be hot (usually red or black) and the other should neutral (usually white but maybe that's your yellow-green).

A bit of following the wires into the machine to see which connects to the motor where will sort those out.

Hello I have an old sewing machine, used once. Given to me by a friend. It is wired to fit into a light fitting. Is it possible to convert to a regular plug fitting. The wires are one red, one yellow with green stripe. Thanks

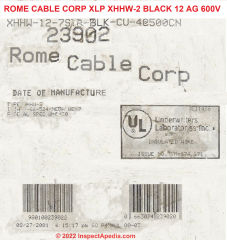

On 2022-04-13 by Inspectapedia Com Moderator - Rome XLP electrical cable is rated for underground use

@,

Rome XLP electrical cable is wire that is rated for underground use, that is, burial, using an XLP - cross-linked polyethylene insulation.

XLP wire is currently sold with stranded copper or aluminum conductors in larger sizes such as may be used for service entry wiring and in smaller sizes using a solid copper conductor for branch circuit wiring used where burial or resistance to moisture or to oil and gas is required.

XLP is popular for use as an alternative to EPR (Ethylene Propylene Rubber insulated wire) where a tougher insulation with more resistance to chemicals is needed.

Your 4/0 copper is sized for use as SEC or service entry wire just as you found. On the wire jacket you'll see

ROME CABLE (UL) XLP XHHW-2 nnn AWG CU 600V E11486

where

nnn= the wire size such as 4/0

Rome Cable Corporation's XLP wire was sold usually with a black or gray insulating jacket.

Keep in mind that XLP wire (rated for wet or burial) can also be used in dry locations and above-ground, as it's also rated to perform against exposure to sunlight. It can also be run in conduit, raceways, and overhead. XLP USE wire is suitable where you might have run RHH and RHW-2 in either wet and dry residential or industrial applications.

In sum, XLP-use wire is similar to other XHHW building wire except for its additional rating for burial. In some references this same wire might be referred to as RHH/RHW wire meeting UL 854 for SEC applications.

Our Rome Cable Corp. XLP XHHW 12 electrical wire label shown here is for a smaller size, #12 AWG.

(Thanks to DWC Distributor Wire & Cable Co. distributorwire.dom for some of these details).

A friend just replaced an old undergroung (urd) service that was 4/0 copper with a #2 open neutral direct buried. The cable says rome-xlp wire cable. The house was built in the 60's I would guess & they were upgrading the service.

He called me because he has never seen this type of cable as neither have I & I have been doing this kind of work for over 40 years. Just asking if anyone else has seen this before?

On 2022-04-06 by Inspectapedia Com Moderator - how can I fix old rubber and fabric wiring?

@Jason,

A doorbell wire or "bell wire" will normally be low-voltage, 24VAC, powered by a low voltage transformer somewhere in your home, often near the electrical panel.

You don't give the country, city, of location nor age of home, but I'm guess ing that that wire, as it looks like rubber and fabric, is pretty old.

If the damage is just at that connection and if you have enough spare length, cut back the damaged wire. Or if necessary, it's reasonable to wrap it in electrical tape.

If you can easily snake a replacement doorbell wire that'd be something to put onto your chore list.

If your worry is about asbestos, (not likely) see ASBESTOS ELECTRICAL WIRE INSULATION - live link in the Recommended Articles list.

We purchased a home, and any wire we can see looks new. I went to pull off the nest doorbell to update it to use our account, and found the following wires. Notice the bare wire section. I wrapped it in electrical tape for now. What kind of wire is this, and should I be concerned?

@Brad.,

Please try including a photo by clicking on the Add Image button and then Comment. That will help us answer your question.

If you are talking about 10 and copper wiring, I don't think there's a special scrap value Beyond its copper content.

Hows it going trying to see if anyone else has came across this very very old Lead/'possibly silver infused & or plated. Ive never in my life seen anything like it. And its thin stranded wire wirh just paper wrapped aroound each indiviual wire.

I have some stuff inch and a half and some stuff 2 inch just want to see if there's any value in scrapping it distinctively

On 2022-02-02 by Inspectapedia Com Moderator - identifying fluorescent wiring

@Hello,

Without being on site with a voltmeter to test each wire to be absolutely certain that we know how they are used I'm afraid it's a bit dangerous for me to tell you what someone else connected.

However what you are looking at are high and low voltage wires in a fluorescent light fixture.

Take a closer look at the ballast, that's that big black rectangular object.

You should see a sticker right on the ballast that has the wiring diagram for that particular light.

You'll see that wires are sent from the incoming Supply voltage to the ballast and from the ballast to the terminals on the fluorescent light fixture and perhaps through a starter cartridge.

A Ground wire in your light fixture will normally be bare copper or possibly green.

If you use the on Page search box to search for the phrase

Fluorescent light wiring repair

You will find our articles that describe exactly how we have wired these fixtures in several configurations.

Post a photo of the drawing or schematic on your fluorescent fixture and I may be able to come in further.

What type of wiring is this where one white and one dark grey are coming from this one cord ? Which would be considered the ground wire?

On 2022-01-20 by Inspectapedia Com Moderator - check old wiring's use and routing with DMM or VOM tool

@Kim,

Sorry but no,; with no information at all about your home and its wiring any guess is such wild speculation as to almost certainly be wrong.

When I find old wires in an old home and their use and routing is unknown,

I use a DMM or VOM or similar test tool to check for live voltage and even if the wire is "dead" I cap off the exposed wire ends for safety.

We live in a mid-50s strawberry box home and redoing the electrical. There's an old disconnected 8 gauge fabric wire that travels from the basement (where the panel is) to the 2nd floor (and possibly to the attic. Does know anyone know what it could have been used for?

@Nick,

@Nick,

Apologies that I wasn't clear enough in my first try at answering.

The electrical safety with respect to the absence of a grounding conductor (ground wire) in knob and tube wiring and in an insulated wire that pairs the hot and neutral wires together but still with no ground, is identical.

The electrical safety of both electrical systems' wires in other regards turns on

- the condition of the wire and its insulation: if the insulation is damaged then it is less safe than when new and in some positions and conditions - such as where someone could touch it and be shocked or where there could be a fire risk - would be unsafe.

- my OPINION and that of some others in the field is that knob and tube wiring, because the hot and neutral wires were run separately and separated by several inches, was inherently safer than wires run together in the same jacket, should both wire sets suffer equal extent of damage to their insulation.

That's because the K&T wires are not only so far apart at most locations as to significantly reduce the risk of a hot-to-neutral short, but also because even where they are supported on or pass through wood framing, the wires are carried on porcelain insulators.

Arguing with myself by adding a dose of real-world conditions: knob and tube, generally never declared as "illegal", may in many buildings be at greater risk of overheating and thus risking a fire because over the ensuing life of a building from its original installation - run in open air - the K&T wires may now be completely covered by added-on building insulation.

That addition violates the original design that depended on being suspended in air to handle the heat generated by use of the circuit. The result exposes the wires to overheating and damaged insulation and thus increased hazard.

More is at KNOB & TUBE WIRING https://inspectapedia.com/electric/Knob_and_Tube_Wiring.php

Thank you for a helpful question.

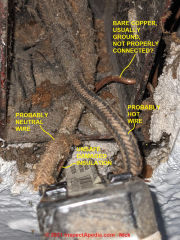

Watch out: for an inch or so (at least) back from its connection to the device the insulation is damaged and partly-lost on at least the neutral wire. I can't see the rest of the wire's insulating jacket - check outside the electrical box and along the wiring passage.

Watch out: we see a bare copper ground but no proper ground wire connections.

@Inspectapedia Com Moderator, Thank you for your reply! I believe it to be tinned copper wire. How much of a risk is the cloth jacket with the degraded rubber insulation inside? Do you believe this type of wire to be as much of a risk as knob and tube wiring?

@Nick,

I see copper wire - check that it's all copper - no aluminum

No-ground: not as safe as modern - you can add grounding

Condition: fabric itself isn't innately a defect, it's the condition of the wire that matters: cracked, damaged, missing, burned, overheated, rat-chewed insulation - needs new wiring in those cases

Watch out: Old electrical wires using rubber insulation are often sporting cracked fragile rubber that may crumble when the wire is handled. Poor-condition rubber wire insulation may reach that state from age alone or from having been exposed to harsh conditions or to overheating.

I bought a house built in 1936, and the previous owner claimed the knob and tube wiring was replaced. Sadly, about 50% of the wiring is as pictured below. Ungrounded and with cloth fiber insulation. It has a black cloth jacket, with two cloth insulated wires inside and a fragile rubber-like insulation against the copper. It's everywhere in the house

. I'm concerned about the safety of this wiring and I would like to know if this is likely from 1936. I can't see any knob and tube wiring in the basement or the attic. These wires are simply put through holes in the joists or stapled to the sides of them. I see some more modern wire with a cloth outer jacket and modern plastic insulation, which I guess was from the 1950's or so, but the majority is as pictured.

[Photo shown above at Moderator's 2nd, more-detailed reply]

@Tim,

From our research we found that standardized electrical wire color coding conventions entered the U.S. National Electrical Code in 1928.

Before that there were some standards such as requirements for wire insulation and wire sizes versus current or amps the wires could safely carry (without overheating to cause a fire) earlier, at least in New York by the NY Board of Fire Underwriters in 1881, and more national wiring standards were in place by 1893.

(The very first national electrical code in the United States, produced by the National Board of Fire Underwriters, was completed by 1897 but without wire color codes).

Currently the U.S. National Electrical Code is sponsored by the NFPA National Fire Protection Association - https://www.nfpa.org/

When did manufacturers start using black-and-white as a color code for a 120 V electrical wiring

@Drew,

@Drew,

That looks like quite-old two-conductor electrical wiring, with no ground visible, just hot and neutral; its jacket or insulation looks as if it may be bitumen-coated fabric;

Where two wires are run in a common external insulating jacket, that's not knob and tube wiring.

But that does NOT mean that there are no knob and tube circuits nearby in the building. And I don't see a ground wire.

So we have 2-wire (with no ground) NMC (Non-Metallic-Cable or what you meant by "Romex") entering the electrical box.

Such wire might be connected to a knob-and-tube system, or not.

It would be useful to know the location of the building, country, city, and the building age.

Watch out: I see that the outer insulating jacket on this wire is cracked - it may be damaged and unsafe.

Trying to figure out if this is knob and tube or Romex

[Photo above]

@Wayne Riley,

On an ungrounded electrical circuit you physically can but legally and safety-wise should not install an electrical receptacle that has a ground hole or opening because you are fooling users into thinking that the receptacle is grounded and safe for equipment that requires a ground for safe operation when in fact that's not the case.

However before deciding that you have to buy a two prong un-Grounded receptacle to install in that location have your electrician open the electrical box and see if a ground is present.

Often there is a ground present and in that case you can install a grounded electrical receptacle or 3-hole receptacle.

if receptacles have no ground hole, does this mean I can't use a 3 hole receptacle

@Meg,

If we can pretend for a moment that the electrical wiring has been installed correctly throughout the building including at this electrical box,

If we can pretend for a moment that the electrical wiring has been installed correctly throughout the building including at this electrical box,

then follow the wires back into the box.

Ground Wire ID: If you see one of the wires connected to the metal box body, typically by a screw or a grounding clip, that should be a ground wire.

Usually the ground wire is bare or sports green insulation or insulation with green and yellow striping.

Hot Wire ID: Another method is to go to the electrical panel and identify the circuit on which this electrical box is wired.

Usually the hot or "live" wire is black, perhaps red, or a combination of red and black.

With power off the electrician would follow the hot wire back to find the cables leaving the electrical panel.

Neutral Wire ID: In the electrical panel neutral wires are connected (usually) to the neutral bus or to a shared neutral and ground bus.

Usually the neutral wire is white.

The electrician might, in the wire cable entering the electrical panel, find the neutral wire and follow in the panel it to its connection on the neutral bus.

There she might temporarily disconnect the neutral wire and cap it.

Now back at the electrical box the ground wire will show continuity to ground using it an ohm-meter or continuity tester, and the neutral wire should not, since it has been disconnected at its other end.

Watch out: if you're not trained and familiar with safe electrical wiring, you should know that you can be shocked or killed.

How do I know which wire is neutral, ground and line?

[Photo above]

...

Continue reading at OLD HOUSE ELECTRICAL SYSTEMS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see OLD ELECTRICAL WIRING FAQs - questions and answers posted originally on this page

Or see these

Recommended Articles

- AGE of a BUILDING, HOW to DETERMINE

- ALUMINUM WIRING IDENTIFICATION

- ANTIQUE & OLD ELECTRICAL RECEPTACLES

- ANTIQUE LAMPS (BULBS) & CONNECTOR TYPES

- ASBESTOS ELECTRICAL WIRE INSULATION

- BULB & LAMP TYPES GUIDE - home

- ELECTRICAL COMPONENTS, AGE, TYPES

- ELECTRICAL GROUNDING in OLDER HOMES

- ELECTRICAL PANEL AGE

- ELECTRICAL RECEPTACLE TYPES

- ELECTRICAL WIRE TYPES CODES USES

- FABRIC NMC WIRE INSULATION IDENTIFICATION

- KNOB & TUBE WIRING

- OLD ELECTRICAL WIRING TYPES

- OLD HOUSE ELECTRICAL SYSTEMS

- SOLID PIPE EDISON DC CABLE HISTORY

Suggested citation for this web page

OLD ELECTRICAL WIRING TYPES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

...

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay. Our Comment Box is provided by Countable Web Productions countable.ca

Technical Reviewers & References

Click to Show or Hide Citations & References

williamsmucatinter.blogspot.com

Source: https://inspectapedia.com/electric/Old_Electrical_Wiring.php

Post a Comment for "Whats Buried Underneath My Ground With 6 Wires Blue Orange White Red"